FTIR Liquid Cells

If you’re looking to prepare your liquid, mull or capillary sample for FTIR analysis look no further! Firebird Optics has you covered with various demountable/sandwich cell configurations along with permanently sealed options.

IR Demountable Mull Cell Assembly (Lightpath: 0.015-1mm)

IR Demountable Mull Cell Assembly (Lightpath: 0.015-1mm)

The Firebird Optics IR Demountable Mull Cell Assembly is a flexible FTIR accessory engineered for efficient analysis of mulls, pastes, slurries, powders, and other solid–liquid mixtures that benefit from transmission sampling. Its demountable design allows the cell to be fully disassembled for thorough cleaning, fast sample loading, and easy reconfiguration — ideal for high-throughput labs or workflows with frequent sample changes and sticky or viscous materials that can foul sealed cells.

This mull cell offers two window size options — 25×4mm and 32×3mm — giving you flexibility to match your pathlength and sample handling needs. The windows themselves are undrilled, providing a clean, unobstructed surface that’s easy to seal and change as needed. Default window material options include UV Fused Silica, KBr, NaCl, BaF₂, CaF₂, Sapphire, Germanium, and ZnSe, making it simple to tailor spectral performance and chemical compatibility across mid-IR and near-IR applications. Built to fit standard FTIR spectrometer mounts and equipped with convenient syringe-ready filling ports, the Firebird Optics IR Demountable Mull Cell Assembly delivers dependable performance, adjustable lightpath flexibility, and user-friendly maintenance for demanding spectroscopy tasks.

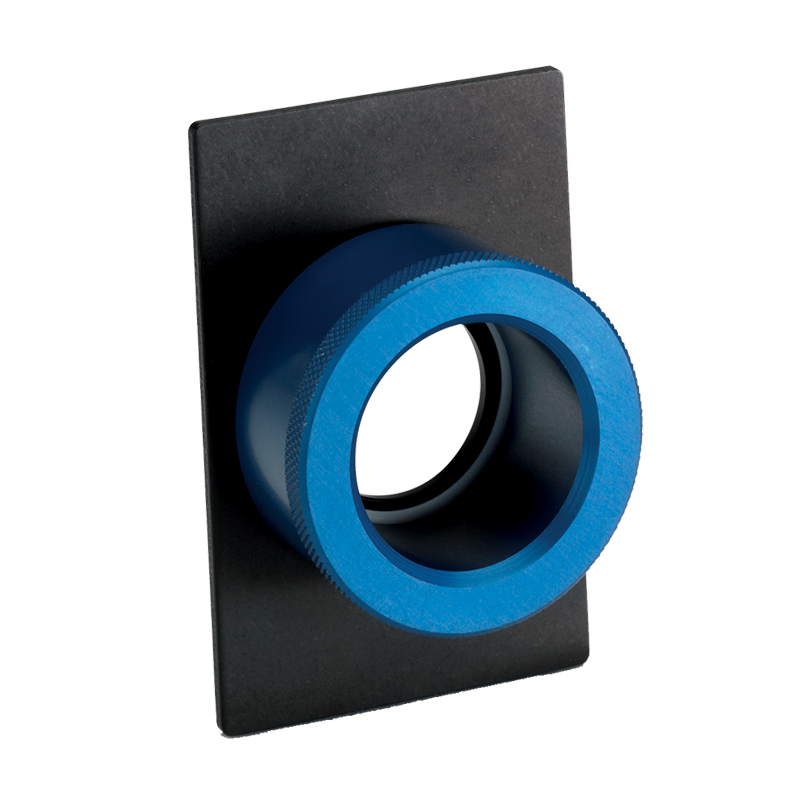

IR Demountable Mull Cell Assembly

The Firebird Optics IR Demountable Mull Cell Assembly is a fast, practical FTIR transmission sampling solution for mulls, pastes, greases, gels, heavy oils, polymers, and other high-viscosity or semi-solid materials that are difficult (or impossible) to load into traditional liquid cells. Instead of pumping a sample through a flow path, you simply place a small amount of material onto an IR window, set a second window on top, and apply controlled pressure to form a thin, IR-transparent film for measurement. This “press-on” approach is one of the quickest ways to get high-quality FTIR spectra from challenging samples with minimal setup and virtually no clogging or downtime.

Designed for routine QC, troubleshooting, and R&D workflows, the assembly is built around a simple demountable format that’s easy to disassemble, wipe clean, and reconfigure between samples. Because the cell creates a thin film by compression, the effective pathlength is variable—it depends on sample viscosity and the pressure applied—making it especially useful for quick screening and for materials where you want to control thickness by feel and technique rather than fixed spacers.

How the Mull Cell Works

A demountable mull cell measures a sample in transmission by sandwiching it between two IR-transparent windows. You place a small amount of sample at the center of the bottom window, position the top window, then use the clamp/cap mechanism to apply pressure. As the sample spreads into a thin layer, it becomes suitable for transmission analysis. This technique is often used for:

Neat, non-volatile liquids that are too thick to syringe or flow

Greases and heavy oils

Mulls (powders dispersed in a mulling agent)

Soft polymers, waxes, gels, and pastes

The biggest workflow advantage is simplicity: there are no internal channels or ports to clog, and cleanup is typically as easy as removing the windows and wiping them with an appropriate solvent.

Key Features and Benefits

Fast sampling for viscous and semi-solid materials

This assembly is purpose-built for samples that don’t behave like liquids. If a material won’t flow, won’t syringe, or leaves residue in traditional cells, the press-on mull format is often the most efficient path to a usable spectrum.

Variable pathlength controlled by pressure

Because you create a thin film by compression, the pathlength is pressure dependent. This can be a major advantage when dealing with strongly absorbing materials—apply a bit more pressure to thin the film and reduce absorbance, or back off slightly for weaker absorbers.

Easy cleaning and rapid turnaround

The demountable construction means the windows are fully accessible. For many samples, cleaning is as simple as wiping both windows with solvent and a lint-free tissue, enabling fast back-to-back testing.

Standard FTIR-friendly mounting

The cell format is designed to integrate smoothly into common FTIR transmission workflows, making it a practical accessory for labs that want consistent, repeatable sample positioning without complicated alignment steps.

Window Sizes and Compatibility

The windows for this mull cell are undrilled, which helps provide a clean optical area and straightforward sealing/contact during compression. Firebird Optics supports two undrilled window size options for this assembly:

25×4 mm (undrilled)

32×3 mm (undrilled)

These sizes let you match your preferred handling, accessory fit, and sampling style. When swapping windows, the key requirements are: undrilled and 25×4 mm or 32×3 mm.

Default Window Material Options

The Firebird Optics IR Demountable Mull Cell Assembly offers a strong set of default window material choices so you can select what best matches your chemistry, durability needs, and spectral region:

UV Fused Silica (UVFS Windows)- 190-2500nm

Potassium Bromide (KBr Windows)- 250nm-26µm

Sodium Chloride (NaCl Windows)- 250nm-20µm

Calcium Fluoride (CaF2 Windows)- 130nm-9.5µm

Sapphire (Al₂O₃ Windows)- 150nm-4.5µm

Germanium (Ge Windows)- 2-16µm

Zinc Selenide (ZnSe Windows)- 1-14µm

Each material offers different advantages. For example, salt windows (like KBr and NaCl) are common in FTIR transmission work, while harder materials (like Sapphire or ZnSe) can be preferred for durability and frequent handling.

Swapping in Other Firebird Optics Windows

If your application requires a different substrate—because of chemical compatibility, durability, or spectral preferences—you can use other window materials available from Firebird Optics as long as they meet the physical requirements:

Undrilled

25×4 mm or 32×3 mm

This gives you flexibility to standardize on the mull cell platform while tailoring the windows to specific sample sets or changing lab needs.

Common Applications

Troubleshooting and rapid identification

This accessory is widely used for fast “what is it?” checks—especially for unknown oils, residues, greases, and polymeric materials where ATR may not be ideal or where you want a complementary transmission spectrum.

QC screening of heavy oils, pastes, and gels

In production and QA labs, the press-on mull method is a quick way to confirm identity, check contamination, or compare batches when samples are too viscous for conventional liquid transmission cells.

Mulls and solid dispersions

For powders that are commonly analyzed as mulls, this cell provides a straightforward way to sandwich the mull between windows and collect clean transmission data with minimal preparation.

Tips for Best Results

Use a very small amount of sample to start—most users apply less than they think they need.

Apply pressure gradually and watch for the film to spread evenly.

If peaks saturate, increase pressure (thinner film) or reduce sample amount.

For messy or reactive samples, consider a more durable window choice to simplify handling and cleaning.

Clean promptly after use to reduce residue buildup and maintain consistent spectral quality.

Features at a Glance

Ideal for qualitative analysis of viscous liquids and mulls

Two diameters available, 25 and 32 mm

Optional spacers for pathlength control

(must select minimum of 2 undrilled if ordering non-standing windows for this cell)