How to Select Probes and Flow Cells for Process Analytical Technology

/What is Process Analytical Technology?

Process Analytical Technology (PAT) is a system of tools, techniques, and methodologies used to monitor and control manufacturing processes in real-time. The goal of PAT is to ensure that manufacturing processes are efficient, consistent, and produce high-quality products.

PAT utilizes advanced analytical techniques such as spectroscopy, chromatography, and other analytical methods to measure critical process parameters (CPPs) such as temperature, pressure, pH, and other process variables in real-time. By monitoring these parameters, manufacturers can identify potential issues and take corrective actions to prevent them from escalating into problems that could affect the quality of the final product.

The implementation of PAT requires collaboration between different departments such as production, quality control, and engineering. It involves the development of robust process control strategies, the design of appropriate measurement and control systems, and the use of data analytics and statistical process control tools to analyze and interpret the data collected during the manufacturing process.

pat enables users to check for measurements in real time rather than extracting a sample and measuring via conventional means

Benefits of Process Analytical Technology

Real-time measurements provided by Process Analytical Technology (PAT) offer several benefits to manufacturers. Some of these benefits include:

Increased process understanding: Real-time monitoring of critical process parameters (CPPs) provides manufacturers with a better understanding of how their manufacturing process works. This information can be used to optimize the process and improve product quality.

Faster detection of process deviations: Real-time measurements allow manufacturers to detect process deviations as soon as they occur. This enables them to take corrective actions quickly and prevent quality issues from occurring.

Reduced process variability: Real-time monitoring of CPPs can help manufacturers reduce process variability, resulting in higher product quality and lower production costs.

Improved process control: Real-time measurements provide manufacturers with up-to-date information about the status of their manufacturing process. This information can be used to adjust process parameters and control the process in real-time.

Increased productivity: Real-time monitoring can help manufacturers identify bottlenecks and other inefficiencies in the manufacturing process, leading to increased productivity and reduced production costs.

Better regulatory compliance: Real-time monitoring provides manufacturers with detailed data about their manufacturing process, which can be used to demonstrate compliance with regulatory requirements.

Downsides of Process Analytical Technology

While Process Analytical Technology (PAT) offers numerous benefits, there are also some downsides that need to be considered. Here are a few potential downsides to implementing PAT:

Cost: Implementing PAT can be expensive, requiring significant investment in equipment, software, and personnel. In some cases, the cost of implementing PAT may outweigh the potential benefits, especially for smaller manufacturers.

Complexity: PAT systems can be complex, requiring specialized knowledge and expertise to design, implement, and maintain. This can be a challenge for smaller manufacturers with limited resources.

Data management: Real-time monitoring generates large amounts of data, which can be challenging to manage and analyze effectively. This requires specialized software and expertise to ensure that the data is captured, stored, and analyzed correctly.

Regulatory compliance: Implementing PAT can require additional regulatory compliance, particularly in industries with strict regulatory requirements such as pharmaceuticals and biotechnology. This can add additional complexity and cost to the implementation of PAT.

Resistance to change: Implementing PAT may require changes to existing processes and workflows, which can be met with resistance from employees who are used to working with traditional methods.

What are the Tools Used for Process Analytical Technology?

Process Analytical Technology (PAT) uses a variety of tools to monitor and control manufacturing processes in real-time. Here are some of the key tools used in PAT:

Spectroscopy: Spectroscopic techniques such as infrared (IR), Raman, and near-infrared (NIR) spectroscopy are commonly used in PAT to measure chemical and physical properties of materials in real-time.

Chromatography: Chromatographic techniques such as high-performance liquid chromatography (HPLC) and gas chromatography (GC) are used in PAT to separate and analyze different components of a sample.

Process sensors: Process sensors are used to measure critical process parameters (CPPs) such as temperature, pressure, pH, and other process variables in real-time.

Data analytics and statistical process control (SPC) tools: Data analytics and SPC tools are used to analyze and interpret the data collected during the manufacturing process, helping to identify trends and patterns that can be used to optimize the process.

Automation and control systems: Automation and control systems are used to control the manufacturing process in real-time based on the data collected from the sensors and other analytical tools.

Multivariate data analysis (MVDA) tools: MVDA tools are used to analyze complex data sets generated by spectroscopy and other analytical tools, allowing manufacturers to identify patterns and correlations that might not be visible with simple data analysis techniques.

Flow Cells for PAT

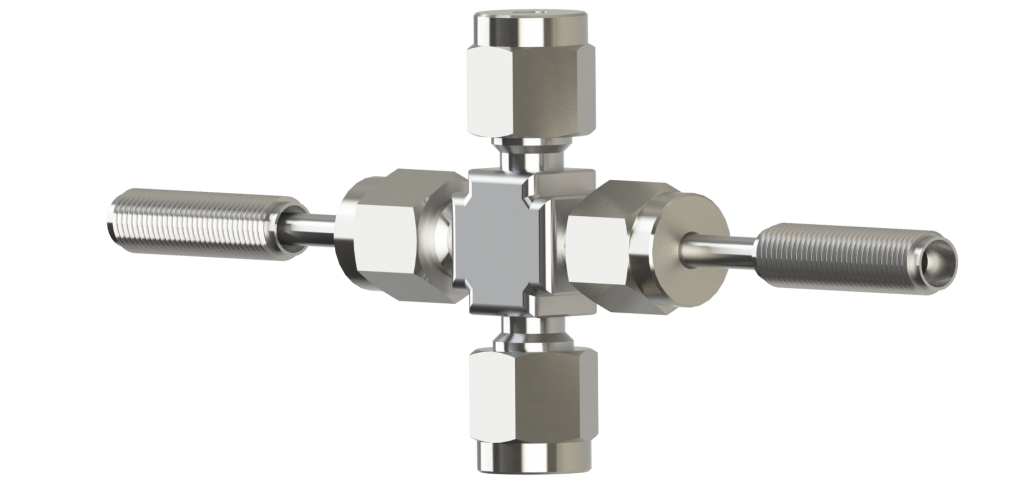

Process Flow Cells are an essential tool in Process Analytical Technology (PAT) as they allow the measurement of critical process parameters (CPPs) in real-time. Flow cells are essentially small chambers that are placed in the path of the process stream, allowing the sample to flow through them continuously. Flow cells can be made of different materials such as glass, quartz, or stainless steel, depending on the application.

Flow cells are commonly used with spectroscopic techniques such as infrared (IR), Raman, and near-infrared (NIR) spectroscopy. The spectroscopic analysis of the sample occurs within the flow cell as the sample passes through it. The flow cell ensures that the sample is presented to the spectroscopic system in a consistent manner, allowing for accurate and reliable measurements of the CPPs.

Flow cells can be designed to be compatible with different types of process streams, including liquid and gas streams. They can also be designed to handle a range of flow rates, depending on the specific application.

The use of flow cells in PAT provides several benefits, including the ability to measure CPPs in real-time, reducing the time required for off-line analysis, and improving the accuracy and reliability of the measurements. Flow cells also allow manufacturers to monitor their processes continuously, making it easier to identify and correct issues as they occur.

Immersion Probes for PAT

Fiber optic probes are another important tool in Process Analytical Technology (PAT). They are used to measure critical process parameters (CPPs) such as temperature, pH, and other process variables in real-time. Fiber optic probes consist of a fiber optic cable that is inserted into the process stream, with one end connected to a light source and the other to a detector.

The fiber optic cable acts as a conduit for light to travel between the light source and the detector. As the light travels through the fiber optic cable, it interacts with the sample, causing changes in the light's properties, such as intensity or wavelength. These changes are then detected by the detector and can be used to determine the CPPs in real-time.

Fiber optic probes can be designed to be compatible with different types of process streams, including liquid and gas streams. They can also be designed to handle a range of temperatures and pressures, depending on the specific application.

Fiber optic probes are commonly used with spectroscopic techniques such as Raman and infrared (IR) spectroscopy. The spectroscopic analysis of the sample occurs within the fiber optic probe as the sample interacts with the light traveling through the cable. The fiber optic probe ensures that the sample is presented to the spectroscopic system in a consistent manner, allowing for accurate and reliable measurements of the CPPs.

The use of fiber optic probes in PAT provides several benefits, including the ability to measure CPPs in real-time, reducing the time required for off-line analysis, and improving the accuracy and reliability of the measurements. Fiber optic probes also allow manufacturers to monitor their processes continuously, making it easier to identify and correct issues as they occur.

Conclusion

Process Analytical Technology is an exciting new field that enables scientists to carry out in-situ measurements rather than ferrying samples back and forth and analyzing via cuvette. The emphasis on real-time measurements and connection via fiber optics, while expensive and a bit more complicated, increases the reliability of measurements and gives a more realistic view in real time.

Whether you decide to go with cuvettes or process tools there are advantages and drawbacks to both options.

Here’s to your success!

Firebird Optics