Optical Windows

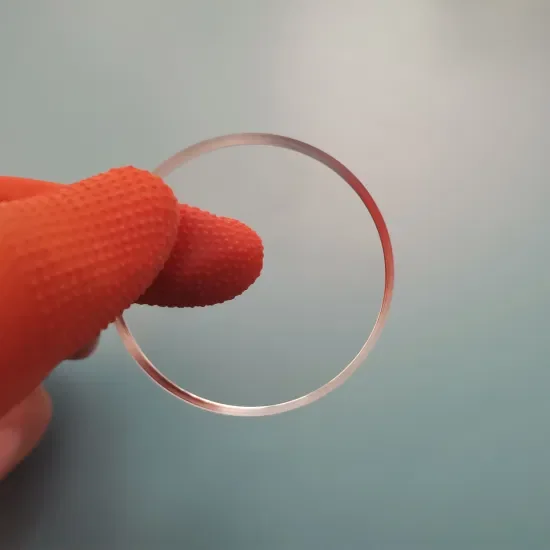

Optical windows are transparent components made of materials like glass or crystal that are used to protect and control the flow of light in optical systems. IR windows and optics for use in FTIR Spectroscopy and CO2 lasers. This includes discs, rectangular plates and various other geometries.

In various fields, optical windows serve many purposes. They act as protective barriers, shielding sensitive optical components from environmental factors such as dust, moisture, and contaminants. Additionally, they enable the transmission of light while minimizing distortion, reflection, and absorption, thus maintaining the integrity of the optical system.

Optical windows are employed in a wide range of applications, including scientific research, industrial manufacturing, aerospace, defense, and telecommunications. They are utilized in optical instruments like cameras, microscopes, telescopes, lasers, and sensors. By providing a stable optical interface, optical windows facilitate accurate measurements, imaging, and analysis of light, enabling advancements in numerous fields.

Optical windows come in many shapes and sizes but a major factor is their material. The types of materials that an optical window is constructed from dictate the wavelengths (measured in nm) that they can view. In IR It is extremely important that selecting the right material is done to avoid many a headache and a waste of money and time.

If you are having choice fatigue and are getting overwhelmed by all the options please check out our optical window guide.

Zinc Sulfide (ZnS) Multispectral-Grade Windows

Zinc Sulfide (ZnS) Multispectral-Grade Windows

Multispectral Zinc Sulfide (ZnS-MS) Windows from Firebird Optics are engineered for advanced optical systems that require broadband performance across visible and infrared wavelengths. Unlike standard FLIR-grade ZnS, which is optimized primarily for long-wave IR, ZnS-MS delivers exceptional transmission from 0.37 µm to 13.5 µm, covering the visible, SWIR, MWIR, and LWIR regions. This broad spectral coverage makes ZnS-MS ideal for multispectral and hyperspectral imaging, dual-band sensors, and visible-to-IR fusion systems.

Manufactured using chemical vapor deposition (CVD) and precision polished to optical-grade clarity, ZnS-MS combines excellent internal transmittance with high durability and low scatter. These properties make it a trusted solution for aerospace domes, infrared windows, and rugged environments where optical performance and mechanical strength are equally critical. Firebird Optics provides ZnS-MS windows in a range of sizes and coatings to support the most demanding system requirements.

What is Multispectral ZnS?

Multispectral Zinc Sulfide (ZnS‑MS) is a water‑clear, polycrystalline IR optical material engineered to pass a very broad spectral band—from ~0.37 to 13.5 µm—so a single optic can support visible, SWIR, MWIR, and much of the LWIR. That visible‑through‑IR reach is the defining advantage versus FLIR‑grade ZnS, which is optimized for IR and not intended for true visible transparency.

ZnS‑MS is widely chosen for windows and lenses in systems that must image in the thermal band (8–14 µm) yet still benefit from visible‑band transmission—for example, to enable visible alignment or to share a “common aperture” among visible and IR sensors.

Both FLIR‑grade ZnS and multispectral ZnS start as CVD‑grown zinc sulfide: zinc vapor reacts with H₂S and deposits as microcrystalline ZnS sheets on heated graphite susceptors, with grain size controlled for strength. Multispectral grade then undergoes hot isostatic pressing (HIP), a high‑temperature, high‑pressure post‑process that removes pores and scattering centers and yields a visibly clear form with extended short‑wavelength transmission.

In practice, that single extra HIP step is what converts a good IR material into a broadband, “water‑clear” optic suitable for simultaneous visible and IR work.

ZnS‑MS vs. FLIR‑grade ZnS

Processing:

FLIR grade: CVD ZnS used essentially as‑deposited (no HIP). Appearance is pale yellow/translucent in the visible. Selected as a tough front optic for thermal imagers, especially in harsh environments.

Multispectral: CVD + HIP → water‑clear and broadband (adds visible/SWIR capability).

Spectral band:

FLIR grade: published transmission band ~8–14 µm (IR‑centric).

Multispectral: ~0.37–13.5 µm, adding the visible and deeper SWIR.

Use‑case emphasis:

FLIR grade: Prioritizes environmental durability as a front window in the 8–14 µm band (e.g., thermal cameras in rain/sand).

Multispectral: Prioritizes broadband imaging (VIS+MWIR/LWIR) and visible alignment, often behind a protective element or where the environment is less erosive.

Selected property contrasts:

Thermal conductivity: ~16.7 W·m⁻¹·K⁻¹ (FLIR) vs ~27.2 W·m⁻¹·K⁻¹ (MS).

Elastic/strength metrics: FLIR data lists a higher apparent elastic limit (on the order of 100 MPa) than MS (tens of MPa), consistent with its use as a “tough front optic.” (Exact values vary by vendor datasheet and test method.)

Practical takeaway: Choose ZnS‑MS when you must combine visible/SWIR with MWIR/LWIR in one optic or need visible‑band alignment through the same aperture. Choose FLIR‑grade ZnS when the optic’s main job is surviving weather/erosion as a front window in the 8–14 µm band.

Applications of Multispectral ZnS

Common‑aperture imaging where a single window must pass both visible and thermal bands (e.g., systems carrying visible + MWIR/LWIR sensors behind one protective element).

Alignment‑friendly thermal optics where visible transmission is useful during system setup/boresighting, yet the optic will operate primarily in the 8–14 µm band in service.

General VIS–IR sensor windows and lenses requiring low scatter/low absorption across a broad band; available with 3–12 µm BBAR coatings for improved throughput.

Design & integration notes

AR coatings are essential: With an index ~2.2 at 10 µm, uncoated two‑surface reflection is ~25% at 10 µm; broadband IR AR coatings (e.g., 3–12 µm) are routinely offered to recover throughput.

Thermal/environmental limits: In air, keep service temperatures ≤ ~250 °C to avoid oxidation and property degradation. For elevated‑temperature or erosive front‑window duty, evaluate FLIR grade or protective sacrificial windows.

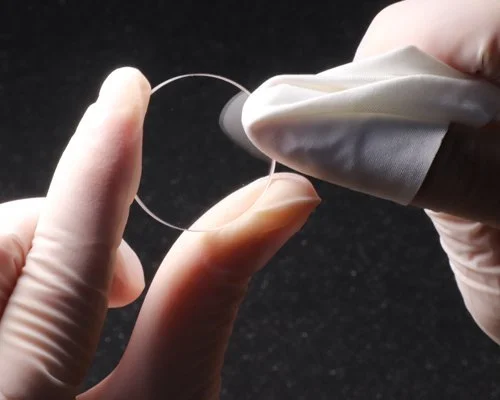

Handling/cleaning: Follow specialty‑optic handling practices; vendors note that acetone may be used with care to remove particulates/debris.

ZnS Multispectral Transmission

| Wavelength range: 0.37-13.5µm | Coating: Uncoated |

|---|---|

| Diameter tolerance: ±0.13mm | Surface Quality: 60/40 |

| Thickness tolerance: ±0.13mm | Paralellism: <3 arc minute |

| Clear Aperture: 90% | Density: 4.09g/cm3 | Melting point: 1827ºC | Young's Modulus: (GPa): 74.5 | Coefficient of Thermal Expansion: 6.5 x 10-6/°C | Knoop Hardness: 240kg/mm2 |

Finding the right optical window can be an exercise in choice fatigue. Let us help!